steel roof ibr sheet roll forming machine

Basic Info

Model No.: as the coustomer requirement

Product Description

Company Information  ZheJiang Willing Technology Co., Ltd. is located in Tongxiang economic development zone, which is about 1 hours far from Shanghai. Product Description IBR ROOF FORMING MACHINE

ZheJiang Willing Technology Co., Ltd. is located in Tongxiang economic development zone, which is about 1 hours far from Shanghai. Product Description IBR ROOF FORMING MACHINE

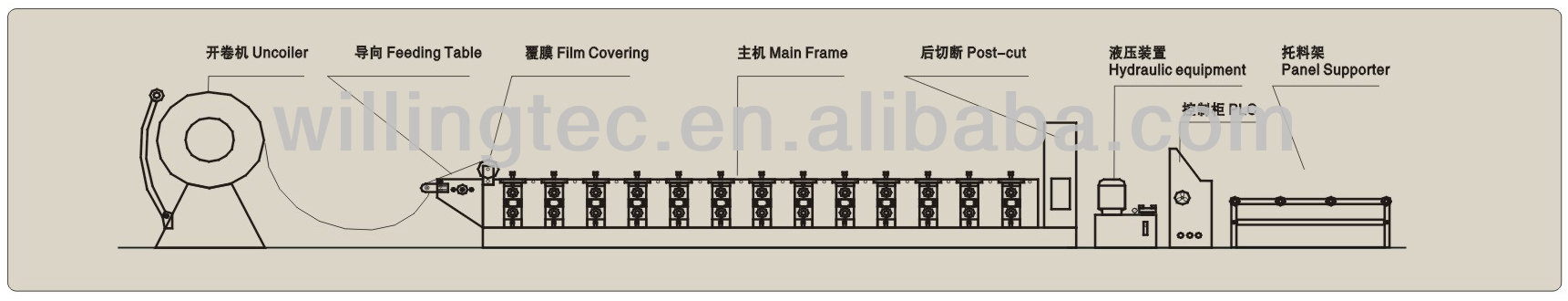

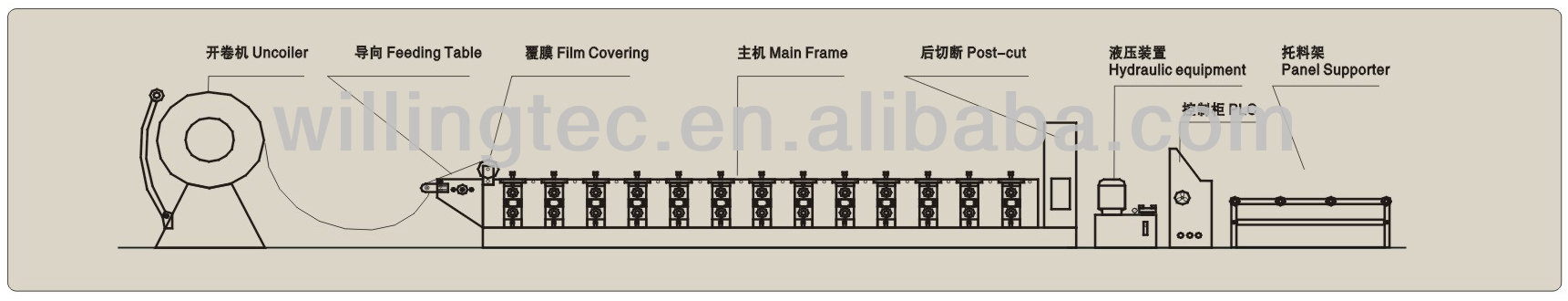

2014 hot sale roof Roll Forming Machine good quality 1.Technical parameter: Material to be rolled PPGI or GI Thickness: 0.2-0.7mm Coil width: 1000mm Effective width: 836mm Material tension grade 550Mpa Voltage: 380V, 3ph, 50hz Main motor power: 4kw Hydraulic power: 3kw Roller: about 17 groups. Lengths: any length can be cutted automatically Cutting way: automatic cutting to length and hydraulic cutting Driving system: chain transmission Forming speed: About 10-12m/min Machine size: About 7500*1500*1300mm (L*W*H) Machine weight: About 6.5 tons 2. Components of machine: 1.Roller Material: high grade No.45 forged steel, Coating with hard chrome. 2.Active Shaft Material: high grade No.45 carbon wrought steel, improved the integrated mechanic feature of the shaft. 3.Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan. 4.Other Elements: from famous suppliers in China. 5.Cutter Blade: Cr12 mould steel with quenched treatment. 3. Process flow: Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic Cutting – product to run out table 4. Details of the machine and wall panel

4. Details of the machine and wall panel  1.Manual decoiler 1> Inner diameter:450-550mm 2>Outer diameter: 1500mm 3>Coil width:1250m 4>capacity: 5T

1.Manual decoiler 1> Inner diameter:450-550mm 2>Outer diameter: 1500mm 3>Coil width:1250m 4>capacity: 5T  2. Forming device

2. Forming device

3.Hydraulic cutting 1>automatic forming, high level safety factor. 2>easy to control, hydraulic cutting after forming

3.Hydraulic cutting 1>automatic forming, high level safety factor. 2>easy to control, hydraulic cutting after forming  4.Control system (touch screen and text screen for choice) 1>Screen:Delta touch screen 2>PLC: Delta 3>automatic length and quantity measurement 4>cutting to length and stop when required quantity is achieved.

4.Control system (touch screen and text screen for choice) 1>Screen:Delta touch screen 2>PLC: Delta 3>automatic length and quantity measurement 4>cutting to length and stop when required quantity is achieved.

We customize your machines! To customize machine, we would love to know:

We customize your machines! To customize machine, we would love to know:

1. Profile drawing

2. Raw material: the width(914mm-1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage:220v/380 or designed on your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ Stacker Have no idea about them?

We will be glad to recommend the lacol popular profile for you----Just let us know your country! Packaging & Shipping

Packaging & Shipping  Contact us if you need more details on Used Metal Roof Panel Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Forming Machine、Corrugated Roof Sheet Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Used Metal Roof Panel Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Forming Machine、Corrugated Roof Sheet Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

ZheJiang Willing Technology Co., Ltd. is located in Tongxiang economic development zone, which is about 1 hours far from Shanghai. Product Description IBR ROOF FORMING MACHINE

ZheJiang Willing Technology Co., Ltd. is located in Tongxiang economic development zone, which is about 1 hours far from Shanghai. Product Description IBR ROOF FORMING MACHINE

2014 hot sale roof Roll Forming Machine good quality 1.Technical parameter: Material to be rolled PPGI or GI Thickness: 0.2-0.7mm Coil width: 1000mm Effective width: 836mm Material tension grade 550Mpa Voltage: 380V, 3ph, 50hz Main motor power: 4kw Hydraulic power: 3kw Roller: about 17 groups. Lengths: any length can be cutted automatically Cutting way: automatic cutting to length and hydraulic cutting Driving system: chain transmission Forming speed: About 10-12m/min Machine size: About 7500*1500*1300mm (L*W*H) Machine weight: About 6.5 tons 2. Components of machine: 1.Roller Material: high grade No.45 forged steel, Coating with hard chrome. 2.Active Shaft Material: high grade No.45 carbon wrought steel, improved the integrated mechanic feature of the shaft. 3.Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan. 4.Other Elements: from famous suppliers in China. 5.Cutter Blade: Cr12 mould steel with quenched treatment. 3. Process flow: Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic Cutting – product to run out table

4. Details of the machine and wall panel

4. Details of the machine and wall panel  1.Manual decoiler 1> Inner diameter:450-550mm 2>Outer diameter: 1500mm 3>Coil width:1250m 4>capacity: 5T

1.Manual decoiler 1> Inner diameter:450-550mm 2>Outer diameter: 1500mm 3>Coil width:1250m 4>capacity: 5T  2. Forming device

2. Forming device

3.Hydraulic cutting 1>automatic forming, high level safety factor. 2>easy to control, hydraulic cutting after forming

3.Hydraulic cutting 1>automatic forming, high level safety factor. 2>easy to control, hydraulic cutting after forming  4.Control system (touch screen and text screen for choice) 1>Screen:Delta touch screen 2>PLC: Delta 3>automatic length and quantity measurement 4>cutting to length and stop when required quantity is achieved.

4.Control system (touch screen and text screen for choice) 1>Screen:Delta touch screen 2>PLC: Delta 3>automatic length and quantity measurement 4>cutting to length and stop when required quantity is achieved. We customize your machines! To customize machine, we would love to know:

We customize your machines! To customize machine, we would love to know:1. Profile drawing

2. Raw material: the width(914mm-1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage:220v/380 or designed on your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ Stacker Have no idea about them?

We will be glad to recommend the lacol popular profile for you----Just let us know your country!

Packaging & Shipping

Packaging & Shipping  Contact us if you need more details on Used Metal Roof Panel Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Forming Machine、Corrugated Roof Sheet Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Used Metal Roof Panel Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Forming Machine、Corrugated Roof Sheet Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Wall And Roof Roll Forming Machine

Premium Related Products

Other Products

Hot Products

Aluminium Gutter Roll Forming MachineHigh Strength Steel Deck Floor Roll Forming MachineCustomized Hex head self drilling screw with rubber wisher from manufacturerFoam EPS sandwich panelCheap cold rolled pre-panited galvalume /PPGL steel heat insulation roof panelHydraulic Press Brake bending machinelength measuring cutting machineChinese manufacturers steel hydraulic uncoilerMading in China Cold rolled steel coil Simple Slitting machineCustomized Embossing Machinesteel C purlins steel roll forming machinesteel and PPGI embossding machinePPGI glazed tile roll forming machine WILLING CompanyConstruction Floor Decking Cold Roll Forming Machinetrapezoidal sheet roof tile wall panel roll forming machine hot in indiansteel Profile roof forming machine