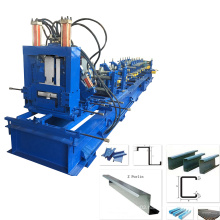

Metal Channel Roll Forming Machine

Basic Info

Model No.: RF-SF

Product Description

Model NO.: RF-SF Place of Orgin: Wuxi, China Roller Stations: 13 Groups Station Material Thickness: 0.5-0.8mm Delivery Time: 50 Days After Deposit Certification: ISO9001: 2000, CE Specification: CE, SGS, ISO HS Code: 8480710090 Name: Metal Channel Roll Forming Machine Exporting Market: Worldwide Main Motor Power: 4kw Forming Speed: 15m/Min Warranty: 12 Months Trademark: Suhang Origin: Wuxi, Jiangsu Metal Channel Roll Framing Machine Specifications 1.rollers be digital processed.

2.High efficiency.

3.Lower cost.

4.Low energy consumption.

5.CE,SGS, ISO certificated. A Main Technical Parameters(for reference) 1.Forming specifications:1000mmx(0.5-0.8mm) 2.Working speed: 15M/min 3.Roller stations: 13 groups station 4.Main motor power: 4kW 5. motor power of hydraulic station: 3kW 6.Material of rollers: fine 45 forge steel, surface coating chrome 7.Material of main shaft: adopted fine 45# steel heating process 8.Diameter of main shaft: φ80mm 9.Pressure of Hydraulic station: 10~12 Mpa 10.Material of cuttng blade: Cr12 quenching process 11.Whole machine adopted PLC control. Cutting length tolerance≤2mm B Flow Chart uncoil ------guide feeding ----- leveling roll forming -----cuting after forming -----output

Our Honorable PrizeMachine Picture

Goods Delivery

Our Honorable Prize

Transportation

All goods will be shipped to your country, containers number will be decided with how many machines would you choose

Installation of the machine

The individual components of the machine are installed according to the layout and prepared for the commissioning.

The installation comprises of:

- Installation by Suhang service technicians.

- The following services are included:

- Installation of the machine components.

- Adjustment of the machine components.

- Connection of all motors to the control cabinet.

- Installation of the required safety devices.

Delivery extent does not comprise of:

- Media supply (electrics, etc. )to the machine(control cabinet)

- Raw material, process material

- Raw material for test

- Transport and lifting devices

- Auxiliary staff.

The operators of the plant should be present during the installation in order to become familiar with the new machines.

Contact us if you need more details on Metal Channel Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stud Roll Forming Machine、Stud Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

2.High efficiency.

3.Lower cost.

4.Low energy consumption.

5.CE,SGS, ISO certificated. A Main Technical Parameters(for reference) 1.Forming specifications:1000mmx(0.5-0.8mm) 2.Working speed: 15M/min 3.Roller stations: 13 groups station 4.Main motor power: 4kW 5. motor power of hydraulic station: 3kW 6.Material of rollers: fine 45 forge steel, surface coating chrome 7.Material of main shaft: adopted fine 45# steel heating process 8.Diameter of main shaft: φ80mm 9.Pressure of Hydraulic station: 10~12 Mpa 10.Material of cuttng blade: Cr12 quenching process 11.Whole machine adopted PLC control. Cutting length tolerance≤2mm B Flow Chart uncoil ------guide feeding ----- leveling roll forming -----cuting after forming -----output

Our Honorable PrizeMachine Picture

Goods Delivery

Our Honorable Prize

Transportation

All goods will be shipped to your country, containers number will be decided with how many machines would you choose

Installation of the machine

The individual components of the machine are installed according to the layout and prepared for the commissioning.

The installation comprises of:

- Installation by Suhang service technicians.

- The following services are included:

- Installation of the machine components.

- Adjustment of the machine components.

- Connection of all motors to the control cabinet.

- Installation of the required safety devices.

Delivery extent does not comprise of:

- Media supply (electrics, etc. )to the machine(control cabinet)

- Raw material, process material

- Raw material for test

- Transport and lifting devices

- Auxiliary staff.

The operators of the plant should be present during the installation in order to become familiar with the new machines.

Contact us if you need more details on Metal Channel Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stud Roll Forming Machine、Stud Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Wall and Roof Panel Roll Forming Machine

Other Products

Hot Products

Aluminium Gutter Roll Forming MachineHigh Strength Steel Deck Floor Roll Forming MachineCustomized Hex head self drilling screw with rubber wisher from manufacturerFoam EPS sandwich panelCheap cold rolled pre-panited galvalume /PPGL steel heat insulation roof panelHydraulic Press Brake bending machinelength measuring cutting machineChinese manufacturers steel hydraulic uncoilerMading in China Cold rolled steel coil Simple Slitting machineCustomized Embossing Machinesteel C purlins steel roll forming machinesteel and PPGI embossding machinePPGI glazed tile roll forming machine WILLING CompanyConstruction Floor Decking Cold Roll Forming Machinetrapezoidal sheet roof tile wall panel roll forming machine hot in indiansteel Profile roof forming machine