Decking Machine,Floor Decking Machine,Floor Decking Forming Machine

Basic Info

Model No.: WLFM51-240-720

Product Description

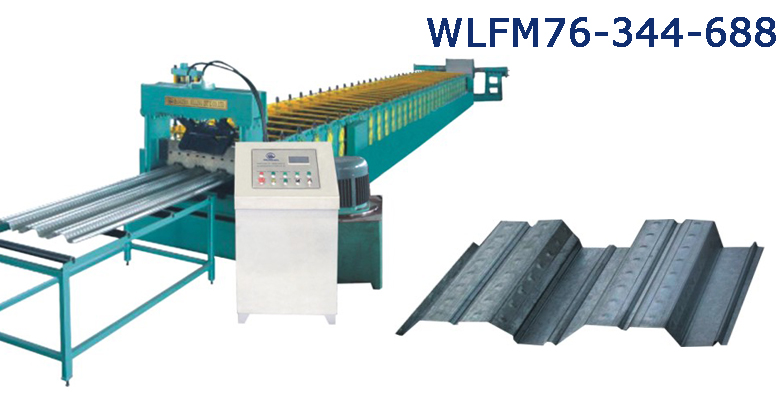

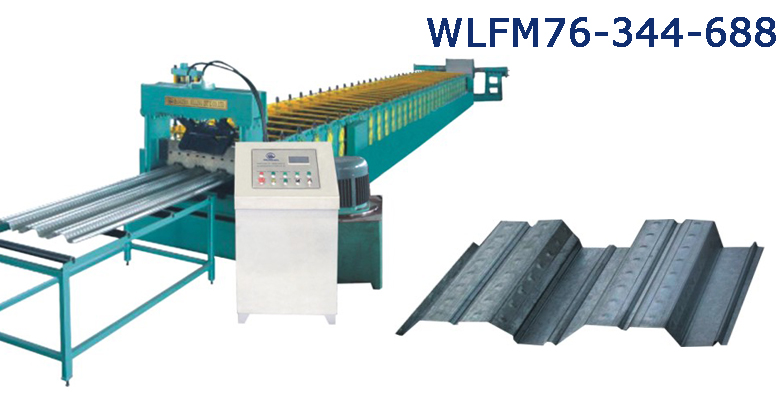

Specifications 1.steel structure Floor Decking Roll Forming Machine

2.Forming Speed:12M/min

3.Steel Thickness:0.7-1.2mm

4.Usage:Used As The

steel structure floor decking Roll Forming Machine Components for the Machine This Roll Forming Decking Machine consists of hydraulic uncoiler and its base, guiding equipment, encoder system, grooving embossing device, roll forming rollers & main machine body frame,post-cut equipment, hydraulic station, PLC control computer desk and run-out supporter table. Technical Parameters Material Spec(Material to be rolled) Material: Q235, Color coated or galvanized Steel coil Thickness: 0.8~1.2mm; Coil width max: 1250mm Coil stress: 235-345Mpa Inner diameter of the coil normally is 508mm and 610 Outer diameter of the coil <1800mm Decoiler: 5TON Hydraulic uncoiler Roll stands: about 27 Main structure wall style entire steel structure, please check the attached machine. Driving system chain transmission Main power about 15KW, depends on the final design. Voltage 380V, 60Hz, 3ph or depends. Main reducer cycloid pin Cutting Hydraulic cutting Power of hydraulic station 4KW, depends on the final design. Material of blade Cr12, heat treated HRC58-62 Measure encoder Controller PLC Forming speed about 12-15m/min Dimension about 15m*1.9m*1.5m Weight about 11 Ton Run-out Table 2 set, one set is 3 meter in length.

Technical Parameters Material Spec(Material to be rolled) Material: Q235, Color coated or galvanized Steel coil Thickness: 0.8~1.2mm; Coil width max: 1250mm Coil stress: 235-345Mpa Inner diameter of the coil normally is 508mm and 610 Outer diameter of the coil <1800mm Decoiler: 5TON Hydraulic uncoiler Roll stands: about 27 Main structure wall style entire steel structure, please check the attached machine. Driving system chain transmission Main power about 15KW, depends on the final design. Voltage 380V, 60Hz, 3ph or depends. Main reducer cycloid pin Cutting Hydraulic cutting Power of hydraulic station 4KW, depends on the final design. Material of blade Cr12, heat treated HRC58-62 Measure encoder Controller PLC Forming speed about 12-15m/min Dimension about 15m*1.9m*1.5m Weight about 11 Ton Run-out Table 2 set, one set is 3 meter in length.  Material of Main Equipment Roller Material Bearing steel with hard treatment Active Shaft Material High grade No.45 carbon wrought steel,can improve the integrated mechanic feature of the shaft Diameter of Shaft 80mm Electric Elements PLC control panel Transducer, PLC Controller, Touched Screen originally imported from Mitsubishiof Japan. Other element from famous suppliers in Chine Cutter Blade Cr12 mould steel with Quench Treatment Component and Function 5 Tons Hydraulic Uncoiler 1set. The uncoiler with pressing arm,, hydraulic system. when loading the coil, the three leafs of the ucoiler expanse, the coil be fixed on the uccoiler, main axis of the uncoiler rotate, the coil sheet comes out. After the coil sheet fed into the roll forming machine, the coil sheet will be pulled back to minimize the pendant. The maximal capacity of 5,000kgs Inner diameter of the Uncoiler: 508mm. Guiding Equipment Adopting 3 separate rolling guider to ensure the sheet is straight into the roll former. At each side of guiding roller, there is threaded shaft, use our special tools, workers can adjust the guiding easily. Mainframe Transmission Transfer the main motor power to the rollers through chains and sprockets, and then transfer the coil sheet. Roll Forming Equipment The panel is formed in this part. Consist of mainframe, rollers and axis. Post-cuttingEquipment The length and blocks can be set by the buyer through the control panel, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. Hydraulic Station Supplies the initial power to the cutting through a closed oil tank. It is off without cutting, which can save the power. PLC Control Panel Buyer can set the parameters through this panel and the machine can be operated automatically after setting. Control the quantity and length automatically.PLC, the whole system is from Japanese Mitsubishi Combined with: PLC, inverter, touch screen, encoder, etc Cut-to-length: tolerance +/- 2mm Control voltage: 24V Run out Table Un-powered: 2 units with bearing transportation. To support the finished panels, it can support panels with length 10,000mm at normal condition To support the finished panels. Machine processing

Material of Main Equipment Roller Material Bearing steel with hard treatment Active Shaft Material High grade No.45 carbon wrought steel,can improve the integrated mechanic feature of the shaft Diameter of Shaft 80mm Electric Elements PLC control panel Transducer, PLC Controller, Touched Screen originally imported from Mitsubishiof Japan. Other element from famous suppliers in Chine Cutter Blade Cr12 mould steel with Quench Treatment Component and Function 5 Tons Hydraulic Uncoiler 1set. The uncoiler with pressing arm,, hydraulic system. when loading the coil, the three leafs of the ucoiler expanse, the coil be fixed on the uccoiler, main axis of the uncoiler rotate, the coil sheet comes out. After the coil sheet fed into the roll forming machine, the coil sheet will be pulled back to minimize the pendant. The maximal capacity of 5,000kgs Inner diameter of the Uncoiler: 508mm. Guiding Equipment Adopting 3 separate rolling guider to ensure the sheet is straight into the roll former. At each side of guiding roller, there is threaded shaft, use our special tools, workers can adjust the guiding easily. Mainframe Transmission Transfer the main motor power to the rollers through chains and sprockets, and then transfer the coil sheet. Roll Forming Equipment The panel is formed in this part. Consist of mainframe, rollers and axis. Post-cuttingEquipment The length and blocks can be set by the buyer through the control panel, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. Hydraulic Station Supplies the initial power to the cutting through a closed oil tank. It is off without cutting, which can save the power. PLC Control Panel Buyer can set the parameters through this panel and the machine can be operated automatically after setting. Control the quantity and length automatically.PLC, the whole system is from Japanese Mitsubishi Combined with: PLC, inverter, touch screen, encoder, etc Cut-to-length: tolerance +/- 2mm Control voltage: 24V Run out Table Un-powered: 2 units with bearing transportation. To support the finished panels, it can support panels with length 10,000mm at normal condition To support the finished panels. Machine processing  loading

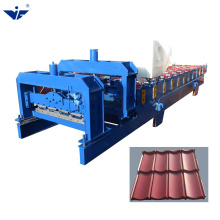

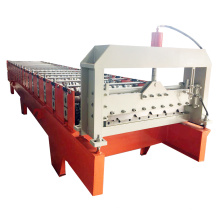

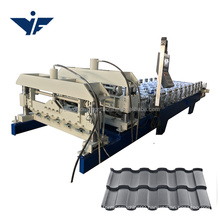

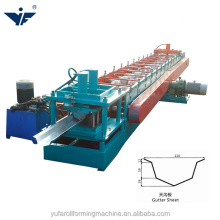

loading  others pics

others pics

Contact us if you need more details on Decking Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Decking Forming Machine、Floor Decking Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Decking Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Decking Forming Machine、Floor Decking Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

2.Forming Speed:12M/min

3.Steel Thickness:0.7-1.2mm

4.Usage:Used As The

steel structure floor decking Roll Forming Machine Components for the Machine This Roll Forming Decking Machine consists of hydraulic uncoiler and its base, guiding equipment, encoder system, grooving embossing device, roll forming rollers & main machine body frame,post-cut equipment, hydraulic station, PLC control computer desk and run-out supporter table.

Technical Parameters Material Spec(Material to be rolled) Material: Q235, Color coated or galvanized Steel coil Thickness: 0.8~1.2mm; Coil width max: 1250mm Coil stress: 235-345Mpa Inner diameter of the coil normally is 508mm and 610 Outer diameter of the coil <1800mm Decoiler: 5TON Hydraulic uncoiler Roll stands: about 27 Main structure wall style entire steel structure, please check the attached machine. Driving system chain transmission Main power about 15KW, depends on the final design. Voltage 380V, 60Hz, 3ph or depends. Main reducer cycloid pin Cutting Hydraulic cutting Power of hydraulic station 4KW, depends on the final design. Material of blade Cr12, heat treated HRC58-62 Measure encoder Controller PLC Forming speed about 12-15m/min Dimension about 15m*1.9m*1.5m Weight about 11 Ton Run-out Table 2 set, one set is 3 meter in length.

Technical Parameters Material Spec(Material to be rolled) Material: Q235, Color coated or galvanized Steel coil Thickness: 0.8~1.2mm; Coil width max: 1250mm Coil stress: 235-345Mpa Inner diameter of the coil normally is 508mm and 610 Outer diameter of the coil <1800mm Decoiler: 5TON Hydraulic uncoiler Roll stands: about 27 Main structure wall style entire steel structure, please check the attached machine. Driving system chain transmission Main power about 15KW, depends on the final design. Voltage 380V, 60Hz, 3ph or depends. Main reducer cycloid pin Cutting Hydraulic cutting Power of hydraulic station 4KW, depends on the final design. Material of blade Cr12, heat treated HRC58-62 Measure encoder Controller PLC Forming speed about 12-15m/min Dimension about 15m*1.9m*1.5m Weight about 11 Ton Run-out Table 2 set, one set is 3 meter in length.  Material of Main Equipment Roller Material Bearing steel with hard treatment Active Shaft Material High grade No.45 carbon wrought steel,can improve the integrated mechanic feature of the shaft Diameter of Shaft 80mm Electric Elements PLC control panel Transducer, PLC Controller, Touched Screen originally imported from Mitsubishiof Japan. Other element from famous suppliers in Chine Cutter Blade Cr12 mould steel with Quench Treatment Component and Function 5 Tons Hydraulic Uncoiler 1set. The uncoiler with pressing arm,, hydraulic system. when loading the coil, the three leafs of the ucoiler expanse, the coil be fixed on the uccoiler, main axis of the uncoiler rotate, the coil sheet comes out. After the coil sheet fed into the roll forming machine, the coil sheet will be pulled back to minimize the pendant. The maximal capacity of 5,000kgs Inner diameter of the Uncoiler: 508mm. Guiding Equipment Adopting 3 separate rolling guider to ensure the sheet is straight into the roll former. At each side of guiding roller, there is threaded shaft, use our special tools, workers can adjust the guiding easily. Mainframe Transmission Transfer the main motor power to the rollers through chains and sprockets, and then transfer the coil sheet. Roll Forming Equipment The panel is formed in this part. Consist of mainframe, rollers and axis. Post-cuttingEquipment The length and blocks can be set by the buyer through the control panel, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. Hydraulic Station Supplies the initial power to the cutting through a closed oil tank. It is off without cutting, which can save the power. PLC Control Panel Buyer can set the parameters through this panel and the machine can be operated automatically after setting. Control the quantity and length automatically.PLC, the whole system is from Japanese Mitsubishi Combined with: PLC, inverter, touch screen, encoder, etc Cut-to-length: tolerance +/- 2mm Control voltage: 24V Run out Table Un-powered: 2 units with bearing transportation. To support the finished panels, it can support panels with length 10,000mm at normal condition To support the finished panels. Machine processing

Material of Main Equipment Roller Material Bearing steel with hard treatment Active Shaft Material High grade No.45 carbon wrought steel,can improve the integrated mechanic feature of the shaft Diameter of Shaft 80mm Electric Elements PLC control panel Transducer, PLC Controller, Touched Screen originally imported from Mitsubishiof Japan. Other element from famous suppliers in Chine Cutter Blade Cr12 mould steel with Quench Treatment Component and Function 5 Tons Hydraulic Uncoiler 1set. The uncoiler with pressing arm,, hydraulic system. when loading the coil, the three leafs of the ucoiler expanse, the coil be fixed on the uccoiler, main axis of the uncoiler rotate, the coil sheet comes out. After the coil sheet fed into the roll forming machine, the coil sheet will be pulled back to minimize the pendant. The maximal capacity of 5,000kgs Inner diameter of the Uncoiler: 508mm. Guiding Equipment Adopting 3 separate rolling guider to ensure the sheet is straight into the roll former. At each side of guiding roller, there is threaded shaft, use our special tools, workers can adjust the guiding easily. Mainframe Transmission Transfer the main motor power to the rollers through chains and sprockets, and then transfer the coil sheet. Roll Forming Equipment The panel is formed in this part. Consist of mainframe, rollers and axis. Post-cuttingEquipment The length and blocks can be set by the buyer through the control panel, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. Hydraulic Station Supplies the initial power to the cutting through a closed oil tank. It is off without cutting, which can save the power. PLC Control Panel Buyer can set the parameters through this panel and the machine can be operated automatically after setting. Control the quantity and length automatically.PLC, the whole system is from Japanese Mitsubishi Combined with: PLC, inverter, touch screen, encoder, etc Cut-to-length: tolerance +/- 2mm Control voltage: 24V Run out Table Un-powered: 2 units with bearing transportation. To support the finished panels, it can support panels with length 10,000mm at normal condition To support the finished panels. Machine processing  loading

loading  others pics

others pics

Contact us if you need more details on Decking Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Decking Forming Machine、Floor Decking Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Decking Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Decking Forming Machine、Floor Decking Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Steel Floor Deck Roll Forming Machine

Other Products

Hot Products

Aluminium Gutter Roll Forming MachineHigh Strength Steel Deck Floor Roll Forming MachineCustomized Hex head self drilling screw with rubber wisher from manufacturerFoam EPS sandwich panelCheap cold rolled pre-panited galvalume /PPGL steel heat insulation roof panelHydraulic Press Brake bending machinelength measuring cutting machineChinese manufacturers steel hydraulic uncoilerMading in China Cold rolled steel coil Simple Slitting machineCustomized Embossing Machinesteel C purlins steel roll forming machinesteel and PPGI embossding machinePPGI glazed tile roll forming machine WILLING CompanyConstruction Floor Decking Cold Roll Forming Machinetrapezoidal sheet roof tile wall panel roll forming machine hot in indiansteel Profile roof forming machine