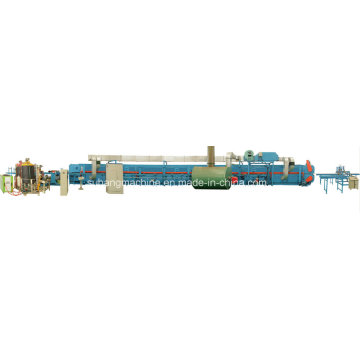

Capacity Quality Ce Certificated PU Foamed Sectional Door Panel Production Line

Basic Info

Model No.: SH-SD

Product Description

Model NO.: SH-SD Condition: New Automatic Grade: Automatic Transmission Method: Electric Suitable Material: Pre-Painted Steel; Aluminum; Platinum Coil Width: 1250mm Length of Sandwich Panel: 3-15m Trademark: Suhang Specification: CE, SGS, ISO9001: 2008 HS Code: 8455229090 Certification: SGS, CE, ISO Customized: Customized Structure: Planetary Name: Sectional Garage Door Panel Roll Forming Machine Material Thickness: 0.4-0.8mm Hardness≤350 Foam Material: EPS \ Polyurethane Speed of Output: 3-7m Transport Package: Film and Steel Origin: Wuxi, Jiangsu Capacity Quality CE Certificated PU Foamed Sectional Door Panel production line

1.Main component of the line:

2.Main Technical Data

Panel Data

Facing layersmaterial: steel

Thickness to be specified

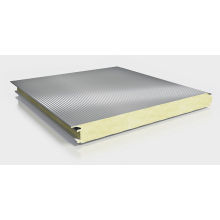

Panel type:Garage door panel

Dimensions of the final product

widthmin: 400mm

max: 600mm

Thicknessmin: 40mm

max: 60mm

Double belt length: 24m

Plant speed: max.10m/min.

min.2, 5m/min

Typical production range 4-6m/min

(Depending on foam system and cutting time)

Working height: 1.300mm

Height of production building:approx. 6m

Electrical Control System:

Temperature of production building: 15 - 35°C

Operating voltage: 380V

Operating frequency: 50Hz

control voltage: 220V

valve voltage: 24V

Signal voltage: 24V

PLC brand: Delta

Contact us if you need more details on Sectional Door Panel Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sectional Door Panel Making Machine、Sectional Door Panel Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.Main component of the line:

| NO. | name | quantity |

| Main roll former | | |

| 1 | Un-coiler (5 tons ) | 2 |

| 2 | Embossing and firm machine | 2 |

| 3 | Automatic feeder and leveler (N.C) | 1 |

| 4 | Press machine(200ton) | 1 |

| 5 | Square mould | 1 |

| 6 | Upper roll former | 1 |

| 7 | Mark machine (N.C) | 1 |

| 8 | Down panel roll former | 2(two types) |

| 9 | Double layer construction platform | 1 |

| 10 | Double bridge device and conveyor | 1 |

| 11 | Other conveyor | 1 |

| 12 | Hydraulic system | 1 |

| 13 | Electrical control system | 1 |

| | | |

| 2. PRE-HEATING SYSTEM | | |

| 1 | Heating house | 1 |

| 2 | pre-heating system | 1 |

| 3 | electrical control system | 1 |

| | | |

| 3.HIGH PRESSURE FOAM MACHINE | | |

| 1 | High pressure continuous foam machine | 1 |

| 2 | Pursing output device | 1 |

| 3 | Electrical control system | 1 |

| NO. | Name | Quantity |

| 4. DOUBLE BELT SYSTEM | | |

| 1 | Double belts system(24M) | 1 |

| 2 | Chain supporting system of two side | 1 |

| 3 | Side-chain system | 1 |

| 4 | Heating machine for double belts | 1 |

| 5 | Electrical control system | 1 |

| | | |

| 5. Thickness and plastic mould | | |

| 1 | Mould & Plastic mould blade | 1 |

| | | |

| 6. CUTTING SYSTEM | | |

| 1 | Cutting saw blade | 1 |

| 2 | Conveyor with output table | 1 |

| 3 | Electrical control system | 1 |

2.Main Technical Data

Panel Data

Facing layersmaterial: steel

Thickness to be specified

Panel type:Garage door panel

Dimensions of the final product

widthmin: 400mm

max: 600mm

Thicknessmin: 40mm

max: 60mm

Double belt length: 24m

Plant speed: max.10m/min.

min.2, 5m/min

Typical production range 4-6m/min

(Depending on foam system and cutting time)

Working height: 1.300mm

Height of production building:approx. 6m

Electrical Control System:

Temperature of production building: 15 - 35°C

Operating voltage: 380V

Operating frequency: 50Hz

control voltage: 220V

valve voltage: 24V

Signal voltage: 24V

PLC brand: Delta

| NO. | ITEM | UNIT | PARAMETERS | REMARK | |

| 1 | PANEL MATERIAL | TYPES | Pre-painted steel; Aluminum; Platinum | CUSTOMIZED | |

| Hardness | MPa | ≤350 | |||

| Thickness | mm | 0.4-0.8 | |||

| Coil width | mm | ≤1250 | |||

| Coil ID | mm | 500.600 | |||

| Coil Weight | T | 5.8.10 | |||

| 2 | FOAM MATERIAL | EPS \ POLYURETHANE | CUSTOMIZED | ||

| 3 | Length of sandwich panel: | m | 3-15 | ||

| 4 | Length of sandwich panel: | mm | ≤1050 | CUSTOMIZED | |

| 4 | Length of sandwich panel: | mm | ≤200 | CUSTOMIZED | |

| 5 | SPEED OF OUTPUT | m/min | 3-7 | ||

| 6 | PRESSURE OF FOAM INJECTION | bar | 150-200 | ||

| 7 | Length of round convey | m | 21 | CUSTOMIZED | |

| 8 | Controller | PLC INVERTER | |||

| 9 | Total Power | Kw | 300 | ||

| 10 | Overall dimensions | m | 110x15x5 | ||

Contact us if you need more details on Sectional Door Panel Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sectional Door Panel Making Machine、Sectional Door Panel Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : PU Sandwich Panel Line

Premium Related Products

Other Products

Hot Products

Aluminium Gutter Roll Forming MachineHigh Strength Steel Deck Floor Roll Forming MachineCustomized Hex head self drilling screw with rubber wisher from manufacturerFoam EPS sandwich panelCheap cold rolled pre-panited galvalume /PPGL steel heat insulation roof panelHydraulic Press Brake bending machinelength measuring cutting machineChinese manufacturers steel hydraulic uncoilerMading in China Cold rolled steel coil Simple Slitting machineCustomized Embossing Machinesteel C purlins steel roll forming machinesteel and PPGI embossding machinePPGI glazed tile roll forming machine WILLING CompanyConstruction Floor Decking Cold Roll Forming Machinetrapezoidal sheet roof tile wall panel roll forming machine hot in indiansteel Profile roof forming machine