Foam EPS sandwich panel

Basic Info

Model No.: willing

Product Description

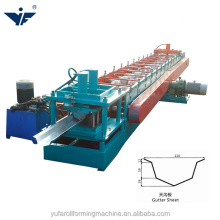

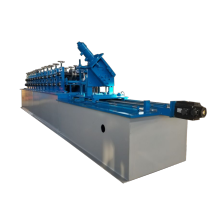

EPS Sandwich Panel Machine Feature: Introductionlaminator for corrugated sandwich panel mainly consists of a Roll Forming Machine

and a sandwich panel laminating system. Through this line, corrugated sandwichpanels can be produced directly, without the shortcoming that traditional corrugatedsandwich panels have to be laminated manually after the forming of corrugatedsheet. Moreover, both the roll forming machine and the laminating system canwork independently. The roll forming machine of the line consists of feeding system,roll forming system and cutting system, while the laminating system is madeup of such equipments as uncoiler, feeding, squeezing, gelatinizing, heating, laminating,edge rolling, edge turn-over, groove-making, edge pruning, pneumaticdevice, automatic cutting and PLC. The whole machine possesses advanced workingcrafts, merging mechanical and electrical equipments into an organic whole. Annualproduction of this line (eight ours a day) is about 600,000 square meters. Features: 1. Beautiful appearance, low noise, high efficiency. 2. Multiple function: In addition to corrugated sandwich panels, this line can be used to produce simple corrugated sheets, and different model sandwich panels. 3. The transmission of the laminating system is achieved by worm and worm gear which make the laminating speed smooth and steady. 4. The line employs advanced PLC and sets the length and cuts the panel automatically.

5. The main body is welded with type "H"section steel as its material. The surface is treated by rotoblast. 6. Rollers of the laminating system are covered with rubber, which is advantageous to the protection of the surface color of galvanized sheets and makes the equipment laminate steadily.

Technical Parameters

Technical Parameters  Machine line specification Work line speed 1000-3000mm/min (frequency speed adjustment). attention:depend on glue brand, temperature and proficiency of operators. Machine length about 40 m Working height 1050 mm(panel output height) Laminating effective length 7.5 m Control way adopt industrial computer PLC Total power about 40 kw power 380V/3phase/50 Hz control voltage 24 V/110 V/220 V pneumatic 0.7 Mpa (self prepared by factory) best working temperature around 25°C

Machine line specification Work line speed 1000-3000mm/min (frequency speed adjustment). attention:depend on glue brand, temperature and proficiency of operators. Machine length about 40 m Working height 1050 mm(panel output height) Laminating effective length 7.5 m Control way adopt industrial computer PLC Total power about 40 kw power 380V/3phase/50 Hz control voltage 24 V/110 V/220 V pneumatic 0.7 Mpa (self prepared by factory) best working temperature around 25°C

Because of the long trip and your super trust, we will make sure Purlin Roll Forming Machine can be appeared in front of you in fully good condition, you will fall in love with it with first glimpse!

Because of the long trip and your super trust, we will make sure Purlin Roll Forming Machine can be appeared in front of you in fully good condition, you will fall in love with it with first glimpse!  Our Services 5.We do our utmost, Why WILLING 1). Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2). Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3). Q: How does your factory do regarding quality control? A: Quality is priority. WILLING People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4). Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5). Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. If you check with WILLING, you will see that we have never got any complaint from our customers. Contact us if you need more details on Eps Raw Material. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wall Panel、Chocolate Raw Material. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our Services 5.We do our utmost, Why WILLING 1). Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2). Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3). Q: How does your factory do regarding quality control? A: Quality is priority. WILLING People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4). Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5). Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. If you check with WILLING, you will see that we have never got any complaint from our customers. Contact us if you need more details on Eps Raw Material. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wall Panel、Chocolate Raw Material. If these products fail to match your need, please contact us and we would like to provide relevant information.

and a sandwich panel laminating system. Through this line, corrugated sandwichpanels can be produced directly, without the shortcoming that traditional corrugatedsandwich panels have to be laminated manually after the forming of corrugatedsheet. Moreover, both the roll forming machine and the laminating system canwork independently. The roll forming machine of the line consists of feeding system,roll forming system and cutting system, while the laminating system is madeup of such equipments as uncoiler, feeding, squeezing, gelatinizing, heating, laminating,edge rolling, edge turn-over, groove-making, edge pruning, pneumaticdevice, automatic cutting and PLC. The whole machine possesses advanced workingcrafts, merging mechanical and electrical equipments into an organic whole. Annualproduction of this line (eight ours a day) is about 600,000 square meters. Features: 1. Beautiful appearance, low noise, high efficiency. 2. Multiple function: In addition to corrugated sandwich panels, this line can be used to produce simple corrugated sheets, and different model sandwich panels. 3. The transmission of the laminating system is achieved by worm and worm gear which make the laminating speed smooth and steady. 4. The line employs advanced PLC and sets the length and cuts the panel automatically.

5. The main body is welded with type "H"section steel as its material. The surface is treated by rotoblast. 6. Rollers of the laminating system are covered with rubber, which is advantageous to the protection of the surface color of galvanized sheets and makes the equipment laminate steadily.

Technical Parameters

Technical Parameters  Machine line specification Work line speed 1000-3000mm/min (frequency speed adjustment). attention:depend on glue brand, temperature and proficiency of operators. Machine length about 40 m Working height 1050 mm(panel output height) Laminating effective length 7.5 m Control way adopt industrial computer PLC Total power about 40 kw power 380V/3phase/50 Hz control voltage 24 V/110 V/220 V pneumatic 0.7 Mpa (self prepared by factory) best working temperature around 25°C

Machine line specification Work line speed 1000-3000mm/min (frequency speed adjustment). attention:depend on glue brand, temperature and proficiency of operators. Machine length about 40 m Working height 1050 mm(panel output height) Laminating effective length 7.5 m Control way adopt industrial computer PLC Total power about 40 kw power 380V/3phase/50 Hz control voltage 24 V/110 V/220 V pneumatic 0.7 Mpa (self prepared by factory) best working temperature around 25°C

Because of the long trip and your super trust, we will make sure Purlin Roll Forming Machine can be appeared in front of you in fully good condition, you will fall in love with it with first glimpse!

Because of the long trip and your super trust, we will make sure Purlin Roll Forming Machine can be appeared in front of you in fully good condition, you will fall in love with it with first glimpse!  Our Services 5.We do our utmost, Why WILLING 1). Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2). Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3). Q: How does your factory do regarding quality control? A: Quality is priority. WILLING People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4). Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5). Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. If you check with WILLING, you will see that we have never got any complaint from our customers. Contact us if you need more details on Eps Raw Material. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wall Panel、Chocolate Raw Material. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our Services 5.We do our utmost, Why WILLING 1). Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2). Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3). Q: How does your factory do regarding quality control? A: Quality is priority. WILLING People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4). Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5). Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. If you check with WILLING, you will see that we have never got any complaint from our customers. Contact us if you need more details on Eps Raw Material. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wall Panel、Chocolate Raw Material. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : EPS Sandwich Roll Forming Machine

Premium Related Products

Other Products

Hot Products

Aluminium Gutter Roll Forming MachineHigh Strength Steel Deck Floor Roll Forming MachineCustomized Hex head self drilling screw with rubber wisher from manufacturerFoam EPS sandwich panelCheap cold rolled pre-panited galvalume /PPGL steel heat insulation roof panelHydraulic Press Brake bending machinelength measuring cutting machineChinese manufacturers steel hydraulic uncoilerMading in China Cold rolled steel coil Simple Slitting machineCustomized Embossing Machinesteel C purlins steel roll forming machinesteel and PPGI embossding machinePPGI glazed tile roll forming machine WILLING CompanyConstruction Floor Decking Cold Roll Forming Machinetrapezoidal sheet roof tile wall panel roll forming machine hot in indiansteel Profile roof forming machine